TECK Highland Valley Copper Mine – New Pebble Crusher Dust Control System Evaluation

CURA provided a complete in-office engineering and field evaluation of the existing dust control system for this enclosed ore crusher facility consisting of two Metso-Nordberg HP400 gyratory cone crushers of 600 Mtph capacity each, driven by 400HP motors.

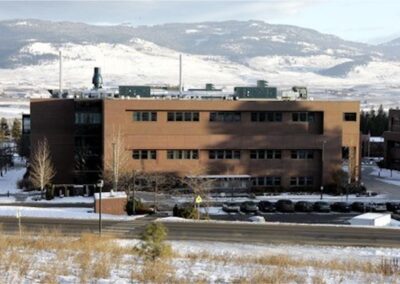

The New Pebble Crusher provides secondary ore crushing of average 4” size (100mm) raw ore pebbles that return as oversizes from the rotary ball mills and the crushing facility is located within a dedicated enclosed building of 36m x 22m footprint that is 28m high.

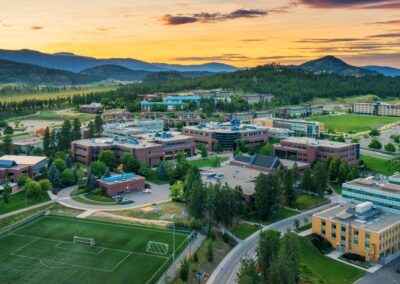

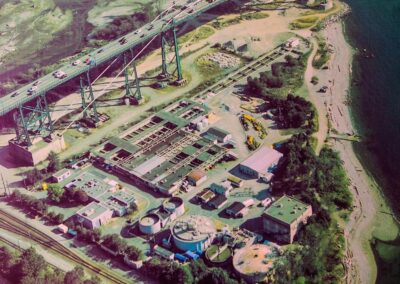

The TECK Highland Valley Copper mine (TECK-HVC) is Canada’s largest open pit copper mine and is located 20 minutes north of Logan Lake BC. Our team was required to become Avetta-compliant & registered to ensure that our firm conformed to TECK’s high standards of site & office safety.

The entire facility’s ore handling equipment, including infeed and outfeed conveyors, surge bins, crusher feeders, crushers, chutes, transfer conveyors & HVAC/makeup air was evaluated by CURA based on modern best practices to determine a recommended retrofit option and a remedy for the myriad of dust escape issues at the facility.

A comprehensive and detailed suite of recommendations for dust system improvements and upgrades was delivered to the TECK-HVC engineering team as part of the mine’s 5-year dust upgrade plan, and CURA’s recommendations targeted a 95% reduction in fugitive particulate escape for the entire crushing facility. Our reporting included a recommendation to add our sister company’s specialized conveyor belt cleaning devices that remove 95% of the fugitive particulate from the return belt surface of horizontal belt conveyors.

The overall project goal targeted a 95% reduction of fugitive particulate.

File Number: 1420-0160.00

Location: Logan Lake, BC

Sector: Industrial, Mining

Services Provided: