Tolko Industries – Lavington Planer – Fire Protection for New Continuous Dry Kiln

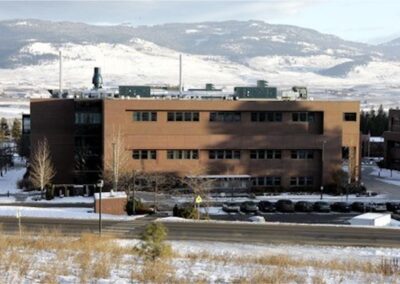

During the planning stages for a new Continuous Dry Kiln system for the Lavington Planer site, Tolko Industries required CURA’s assistance to ensure that the site’s fire protection water supply was adequate for the increased fire protection demand of the proposed new continuous dry kiln (CDK).

The customer was concerned that major infrastructure upgrades to the site’s fire protection water supply could be required to facilitate the addition of the kiln, such as larger piping, booster pumps or by adding underground watermain piping loops.

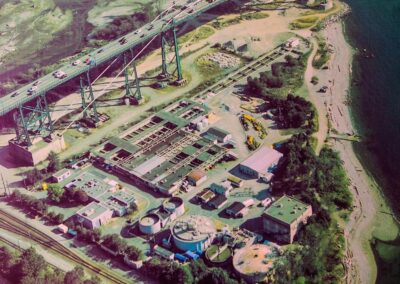

We completed a preliminary estimate of the kiln’s water pressure and flow demand to first define the issue at hand. CURA then utilized our fire protection engineering experience to review the site water supply issue through a different lens, and we were able to advise the client on how to re-set the delivery pressures of the site’s existing paralleled pressure reducing valves (PRVs) to increase water delivery to the site, thus eliminating the cost and complication of major site fire protection water supply upgrades or booster pump systems. A before and after in-situ hydrant flow demand test of the water supply was performed to confirm the calibration and delivery of the site water supply PRVs to meet the water demand of the kiln.

By defining the client’s issues early in the project process, we were able to save the customer a considerable amount of capital expenditure by simply re-using and resetting the operating setpoints of existing water delivery equipment on site, rather than constructing a new booster fire pump facility.

We then provided the fire protection design of the underground site water supply piping to the kiln.

Please contact us for any fire protection engineering assignments as well as fire hydrant flow/demand testing.

File Number: 1420-0031.00

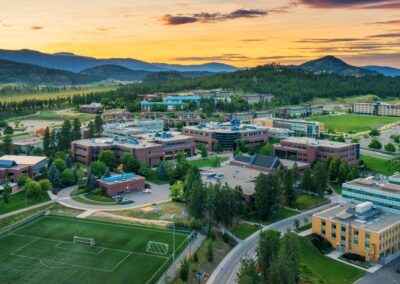

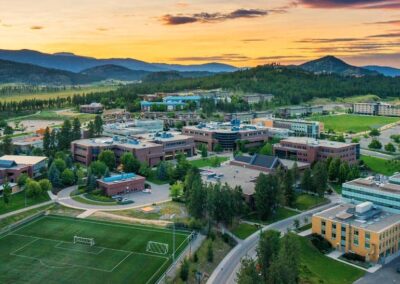

Location: Lavington, BC

Sector: Industrial, Manufacturing

Services Provided: